|

Downton Brickyard

|

|

Downton Brickyard

|

Downton Brickyard

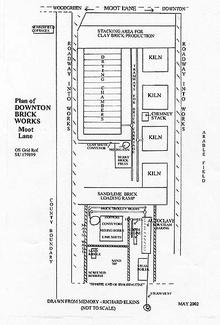

The Downton Brickyard in Moot Lane was the last of a long line of such works in the Downton and Redlynch area which was noted for the production of a variety of high class bricks.

|

|

Opening

Owned by Chas Mitchell & Sons Ltd, the Moot Lane yard opened around 1935 and initially, as well as producing traditionally fired bricks, used a modern technique to make ‘sand lime’ bricks. These yellowy white bricks were made by a different and much quicker method using a mix of quick lime and local sand. The mixture was conveyed to a rotary brick press which moulded them under great pressure. Trolleys on rails then each carried 1,000 bricks straight into a giant autoclave which could hold 17 such trolleys. Steam at a pressure of 120 lbs/sq inch then cured them for 12 hours. This plant was scrapped around 1960 due to a fall in demand for this type of brick. The autoclave, boiler and steam engine with a giant 16 foot flywheel were either demolished or sold.

Plan drawn by Richard Elkins from memory.

|

|

Manufacture

Brick making continued using the traditional kiln firing method but with a mechanised production line which had started up in the mid 1950s. Much of the machinery was second hand from other brickworks – the wet pan for clay mixing came from Shropshire and was made around 1900. The clay was dug from pits around the site. At this time about 20 people were employed. The work was hard and carried some risks.

|

|

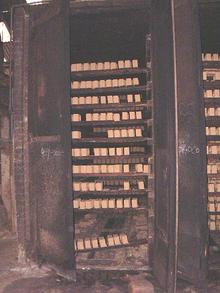

Kilns

Initially there were 2 coal-fired kilns. A complete firing took around 6 days.

More kilns built later were oil-fired.

|

|

Drying

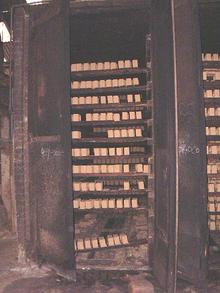

Waste heat from the kilns was used to heat large drying chambers where bricks were stacked prior to firing.

|

|

New Forest Brick Co.

The works closed in 1991, but opened again briefly in 1998 as New Forest Brick. Mechanised brickmaking was supplemented by a manual line producing high class hand made bricks.

|

|

Closure

Unfortunately, the works was forced to close abruptly in March 2000, leaving kilns and dryers full of un- fired bricks. Planning permission for houses was then applied for on the site.

|

|

Demolition Survey

Before demolition took place, a full survey of the buildings and equipment was carried out by Kevin Stokes from the Bursledon Brick Museum as a condition of the planning permission. Members of SWIAS carried out a photographic survey. Some equipment and bricks were removed to the Bursledon Museum where they are on display among other labelled exhibits.

|

|

Disposal of equipment

Finally, all the unfired bricks and remaining equipment were loaded onto lorries and taken to the brickworks of H.T. Mathews in Buckinghamshire, to start life again.

|

|

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()